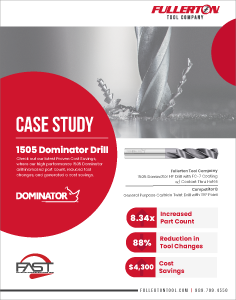

Case Study | 1505 Dominator drill

Check out our latest Proven Cost Savings, where our high performance Dominator drill increased part count by 8.34 times, reduced in tool changes by 88%, and generated a cost savings of over $4,300.

Fullerton 1505 Dominator Drill

Fullerton 1505 Dominator Drill  Competitor B GP Carbide Twist Drill

Competitor B GP Carbide Twist Drill

Fullerton Tool Company

1505 Dominator Drill with FC-7 Coating

with Coolant Thru Holes

Competitor B

General Purpose Carbide Twist Drill with 118° Point

Test Location: New York

Industry: Mold & Die

Operations Executed: Drilling

Processed Material: Case Hardened Steel 56RC

Machining Conditions - Fullerton: 500 RPM/82 SFM, .005 IPR 2.5 IPM, .100 Peck, 4" Deep

Machining Conditions - Competitor: 500 RPM/82 SFM, .005 IPR 2.5 IPM, .100 Peck, 4" Deep

Parts Machined - Fullerton: 250 Parts/Tool

Parts Machined - Competitor B: 30 Parts/Tool

Download Case Study

Fullerton's 1505 Dominator High-Performance Drill produced 8.34x more parts compared to Competitor B's General Purpose Carbide Twist Drill. Fullerton's Dominator Drill machined 250 parts per tool versus Competitor B Twist Drill which machined 30 parts per tool. This has also led to an 88% reduction in tool changes and over $4,300 in cost savings.

Find available 1505 Dominator offering at https://fullertontool.com/resources/tool-search?&tool_type_id=DR&uom=imperial&series_id=1505

Start generating cost savings by contacting our sales team!

Interested in finding out how you can start generating cost savings for your business? Contact your dedicated Fullerton sales contact to get started. Find your dedicated sales team at https://fullertontool.com/contact/locator.