Case Study | 3116 timill End Mill

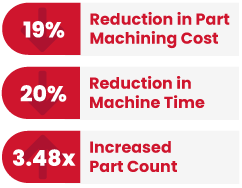

Check out our latest Proven Cost Savings, where our high performance end mill reduces in part machining costs, machining time, and generates more parts per tool.

Fullerton Tool Company

3116 TiMill End Mill Radius with FC-13 Coating

Versus

Competitor B

HP End Mill Radius with Coating

Test Location: Kansas

Industry: Aeropace

Operations Executed: Roughing

Processed Material: Titanium 6AL4V

Machining Conditions - Fullerton: 1121 RPM/220 SFM, .008 FPT/53.79 IPM, .040 ADOC, .040 RDOC

Machining Conditions - Competitor: 1121 RPM/220 SFM, .008 FPT/44.82 IPM, .040 ADOC, .040 RDOC

Parts Machined - Fullerton: 150 Parts/Tool

Parts Machined - Competitor B: 43 Parts/Tool

Fullerton's 3116 TiMill Radius end mill created a 19% reduction in part machining costs.

Find available 3116 TiMill offering at https://fullertontool.com/resources/tool-search?&tool_type_id=EM&uom=imperial&series_id=3116

Or download the Case Study at https://fullertontool.com/media/Fullerton-CaseStudy-3116-TiMill.pdf

Start generating cost savings by contacting our sales team!

Interested in finding out how you can start generating cost savings for your business? Contact your dedicated Fullerton sales contact to get started. Find your dedicated sales team at https://fullertontool.com/contact/locator.