Here at Fullerton, not only are we dedicated to creating extraordinary carbide cutting tools, but we're also extremely focused on providing the best solutions for our customers and producing guaranteed cost savings. Check out this case study on our 3500 Fury high-performance end mill where we were able to reduce the time per part, cost per part, and generate over $20,500 in savings for our customer.

Tooling:

Fullerton 3500 Fury End Mill XL Ball with FC20 Coating

Versus

Competitor C HP End Mill Ball with TiN Coating

Highlights:

Time Per Part:

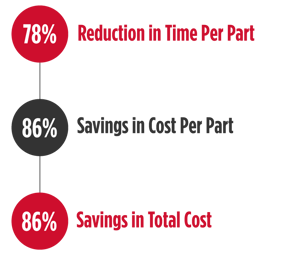

Our 3500 Fury XL high-performance end mill reduced the time per part by 14 minutes. Our Fury had a cycle time of 4 minutes per part, versus Competitor C's 18-minute cycle time per part resulting in a 78% reduction in time per part.

Cost Per Part:

Our 3500 Fury XL high-performance end mill produced a $342.35 cost savings per part. Our cost per part was $56.64 compared to Competitor C's cost of $399 resulting in a 86% savings in cost per part.

Savings in Total Cost:

Our 3500 Fury XL high-performance end mill produced an overall proven cost savings of $20,500, with our total cost of $3,398.60 compared to Competitor C's cost of $24,940 resulting in a 86% savings in total cost.

Our 3500 Fury high-performance end mill generated over $20,500 in cost savings.

Check out our available 3500 Fury offering by clicking the button below or by visiting https://fullertontool.com/search?&tool_type_id=EM&uom=imperial&series_id=3500

Start generating cost savings by contacting our sales team!

Interested in finding out how you can start generating cost savings for your business? Contact your dedicated Fullerton sales contact to get started. Find your dedicated sales team at https://fullertontool.com/contact/locator