Tool Tip - Guidelines for Deep Hole Drilling: Pilot Hole

When it comes to deep hole drilling, there are certain procedures and factors that are particularly important for ensuring reliable machining. The Deepmax is tailored to Inovatools' 5xD 207 Series standard drills, which are the ideal pilot drills.

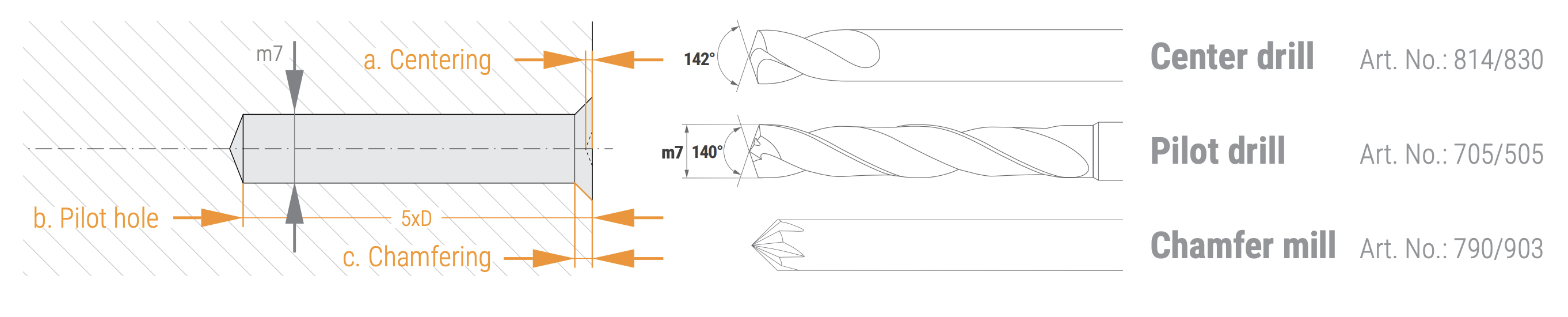

Pilot Hole:

- Uneven surfaces must be faced or face milled prior to drilling the pilot hole. (We also recommend centering the workpiece.)

- Use a two flute drilling tool with a 140 degree point angle and an m7 tolerance range. (Should you be using a third-party product as your pilot drill, please make sure pilot drill diameter is M7 tolerance.)

- The pilot hole should ideally have a depth of 5xD or at least 1.5xD.

- Centering and subsequent chamfering is absolutely essential for horizontal machining.

- Any chips must be removed from the pilot hole prior to drilling the deep hole.

Download our Inovatools catalog to view an offering of our available Deepmax deep hole drills at https://fullertontool.com/media/Fullerton_Inovatools_Catalog.pdf or by clicking the button below.