Our solid carbide reamers are designed to enlarge the size of an existing hole with a high degree of accuracy, consistency, and predictability.

General conditions for reamer use and their results can vary widely based on material condition, tool configuration and equipment. Performing reaming correctly, however, requires good preparation and attention to detail. Important factors include Speeds and Feeds, leaving the exact amount of stock after drilling and specifying the right reamer for the job. Generally, reamers are only meant to remove 2-3% of the desired size. Here are some special considerations to keep in mind, which are useful in many of your everyday applications.

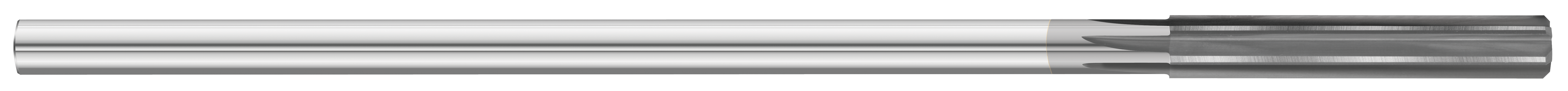

Straight Flutes|Right-Hand Cutting

Recommended for all general purpose applications.

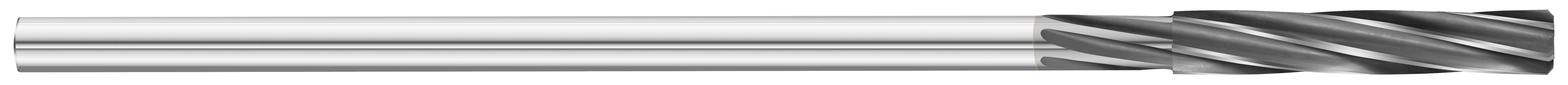

Right-Hand Spiral Flutes|Right-Hand Cutting

Recommended for blind holes and abrasive, ductile materials.

Left-Hand Spiral Flutes|Right-Hand Cutting

Allows for better finishes on hard materials, such as heat treated steels. Left-hand shear action is excellent for holes with interruptions. Because the reamer follows the existing hole and does not correct straightness or position, adding bore/ream geometry can greatly improve both straightness and true position.

It is not always necessary to have long flute lengths on reamers. In some applications, a long flute length will improve performance; however, in a large majority, standard lengths are more sufficient. For example, when reaming a hole that is Ø.312 diameter 2” deep, the flute length on the standard 5/16” carbide tipped reamer is 1.125”. You don’t need a reamer with 2” of flute to ream this hole. The 1.125” flute length is sufficient.

Always keep your reamers sharp, clean and protected.

Never reverse rotation on a reamer and never pull it out without rotating it.

Special coolant thru reamers are also available with either branch feed holes for thru hole applications, while many times single bore on axis configurations are more than sufficient for blind hole applications.

Have additional questions about our Reamers? Contact our Engineering department at 800.248.8315.