Tool Tip - Guidelines for Deep Hole Drilling: Deep Hole

When it comes to deep hole drilling, there are certain procedures and factors that are particularly important for ensuring reliable machining. The Deepmax is tailored to Inovatools' 5xD 207 Series standard drills, which are the ideal pilot drills.

Deep Hole:

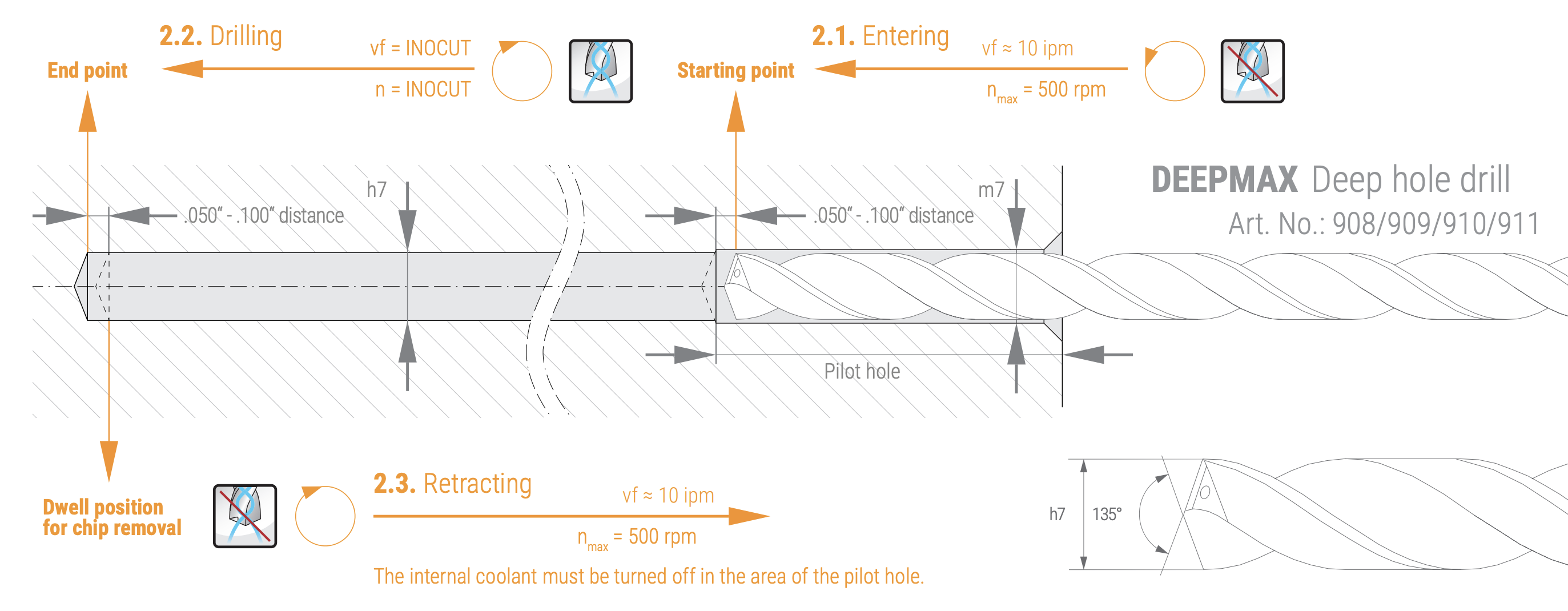

2.1. Entering the deep hole drill into the pilot hole

- The internal coolant must be turned off for this procedure.

- Set a maximum rotation speed of 500 rpm, preferably with anti-clockwise rotation, and a feed rate of around 10 ipm.

- Enter the drill to 0.050"-0.100" short of the bottom of the pilot hole.

2.2. Deep hole drilling

- Please make sure you allow enough dwell time or the spindle to start and the internal coolant to build up pressure.

- We recommend using Inovatools' INOCUT tooling data without chip evacuation (peaking). It should not be necessary to retract the drill for holes up to 30xD. Should additional chip removal be required, we recommend retracting the drill to 3xD. When reaching intersecting holes or making through holes, reduce the feed rate by 50% prior to breakout.

2.3 Retracting the deep hole drill

- After reaching the maximum depth, retract the deep hole drill by 0.050"-0.100" (depending on the diameter) for chip removal. If the coolant pressure is too low, you might need to program some dwell time.

- Then reduce the rotation speed to a maximum of 500 rpm.

- Retract the drill out of the hole at a programmed feed rate of around 40 ipm max (not in rapid traverse).

Download our Inovatools catalog to view an offering of our available Deepmax deep hole drills at https://fullertontool.com/media/Fullerton_Inovatools_Catalog.pdf or by clicking the button below.