Have you noticed Fullerton’s Saw feeds are much greater than other saw manufacturers? The reason is radial chip thinning. Radial chip thinning is all the buzz in newer advanced tool paths associated with high efficiency machining, but Fullerton has been employing these techniques for years in our 2450 Ferrous Saws and our new 2455 Non-Ferrous Saws.

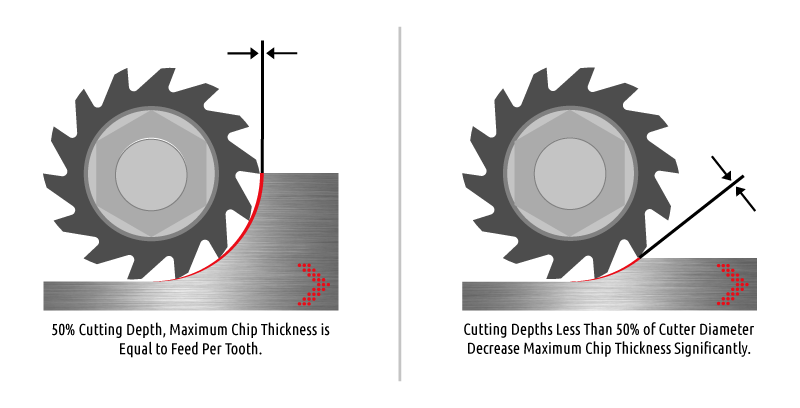

Radial chip thinning involves two separate but unique paramaters, chip thickness and feed per tooth. These two values are often mistaken as the same, but they are separate variables that have a direct impact on each other.

CHIP THICKNESS

Chip thickness is the thickness of each chip cut by a tool, measured as its largest cross-section.

FEED PER TOOTH (IPT/Chip Load)

Feed per tooth translates directly to your tool feed rate and is commonly referred to as IPT or chip load.

In the case of an arbor mounted saw, these two values will almost never be the same. The limitation is based on the arbor hole and work holding requirements of the saw blade. Once the radial depth of cut falls below centerline, the required clearance plane for arbor the maximum chip thickness decreases. This can lead to severe loss in productivity and premature tool wear. Adjustment of running parameters to optimize chip thickness ensures increased metal removal rates and improved tool life.

EXAMPLE