Let's kick off our Custom Tool of the Month series with a serious showstopper - a form tool so efficient, it booted an entire machining center out of the process and saved our customer a jaw-dropping $280,000 a year. Yeah...you read that right.

Our Customer's Situation:

Our customer was using two machines to get the job done. First, the part was turned on a Swiss-style lathe and parted off. Then it took a field trip to a milling center, where multiple tools were needed to shape the part just right.

We saw an opportunity - and we ran with it.

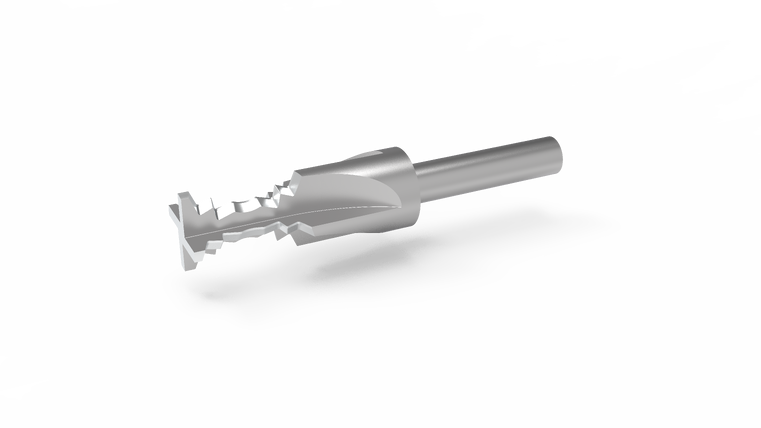

Our team designed a custom form tool made to run in the live tooling bed of their Swiss-style lathe. That meant everything - turning, milling, shaping - could now happen before the part was even parted off.

The result?

- No more milling center required.

- Cycle time slashed from minutes to seconds.

- Freed up a whole machining center for more production.

- Annual savings ringing in at $280,000

This custom cutter didn't just streamline production - it reshaped the entire workflow.

Want to explore what a Fullerton-made cutter could do for your shop? Let's make something amazing together. Learn more at fullertontool.com/resources/custom-tooling