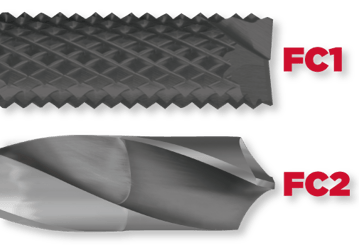

Here at Fullerton, we have various types of coatings, but our FC1 coated tools are one of the strongest and durable types of cutting tools. Our FC1 coating is a layer of diamond that is bonded to the carbide tool. This coating requires special carbide grades. Because of this, the only standard tooling this coating can be added to is our MATRX line of tooling. The MATRX line is available in a low wear grade of carbide that works well in abrasive materials without coating and much better with a layer of FC1 added. We can also manufacture specials out of the special carbide grade that will take the FC1 coating. This coating works great in Carbon Fiber Reinforced Plastics (CFRP), Metal Matrix Composite (MMC), and other highly abrasive materials.

An alternative to the FC1 coating is our FC2 coating. The FC2 coating is a layer of hard carbon added to the cutting tool. The next best thing to diamond when cutting abrasive materials. FC2 is a little easier on the pocketbook but there is a tradeoff. The FC1 will outlast the FC2 in most cases. Some advantages of FC2 over FC1 is we are left with a sharper cutting edge, it can be added to any stock tool or carbide grade and the tool can be reground and re-coated.

If you aren't sure which coating is best for your application, feel free to call us for recommendations at 800.248.8315 or check out our website for more information.