This Tool Tip features useful information on effective feed rates, chip thinning using a Ball Nose and understanding angle of attack (AoA). Check out our Tool Tip below.

As materials change, the cutting tools developed to machine those materials must change. It is important to understand proper ways to control the feed rates at the Angle of Attack (AoA) on the workpiece.

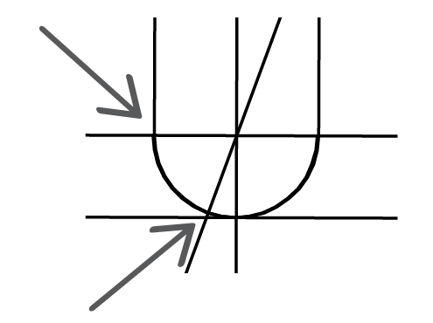

Chip thinning occurs at the cutting edge and important to remember when maintaining effective feed rates at the cutting edge. Also, it is very important when using a ball nose to understand the change in speed when moving closer to the center of the tool. See example shown below.

Example: .500" Diameter and an Angle of Attack (AoA) of 20 degrees

Chip thickness at full diameter.

As programmed .005" IPT

Chip Thinning at the Angle of Attack (AoA).

In this example the AoA is 20 degrees.

IPT is .0017" at the AoA

SFM is 72 SFM - The diameter at the contact zone is only .17"

Programmed SFM is 200 at a full .500" tool diameter

Thanks for checking out our tool tip about effective feed rates, chip thinning using a Ball Nose and understanding angle of attack (AoA). If you have any additional questions, please contact our Engineering team at 989.799.4550 or engineering@fullertontool.com.