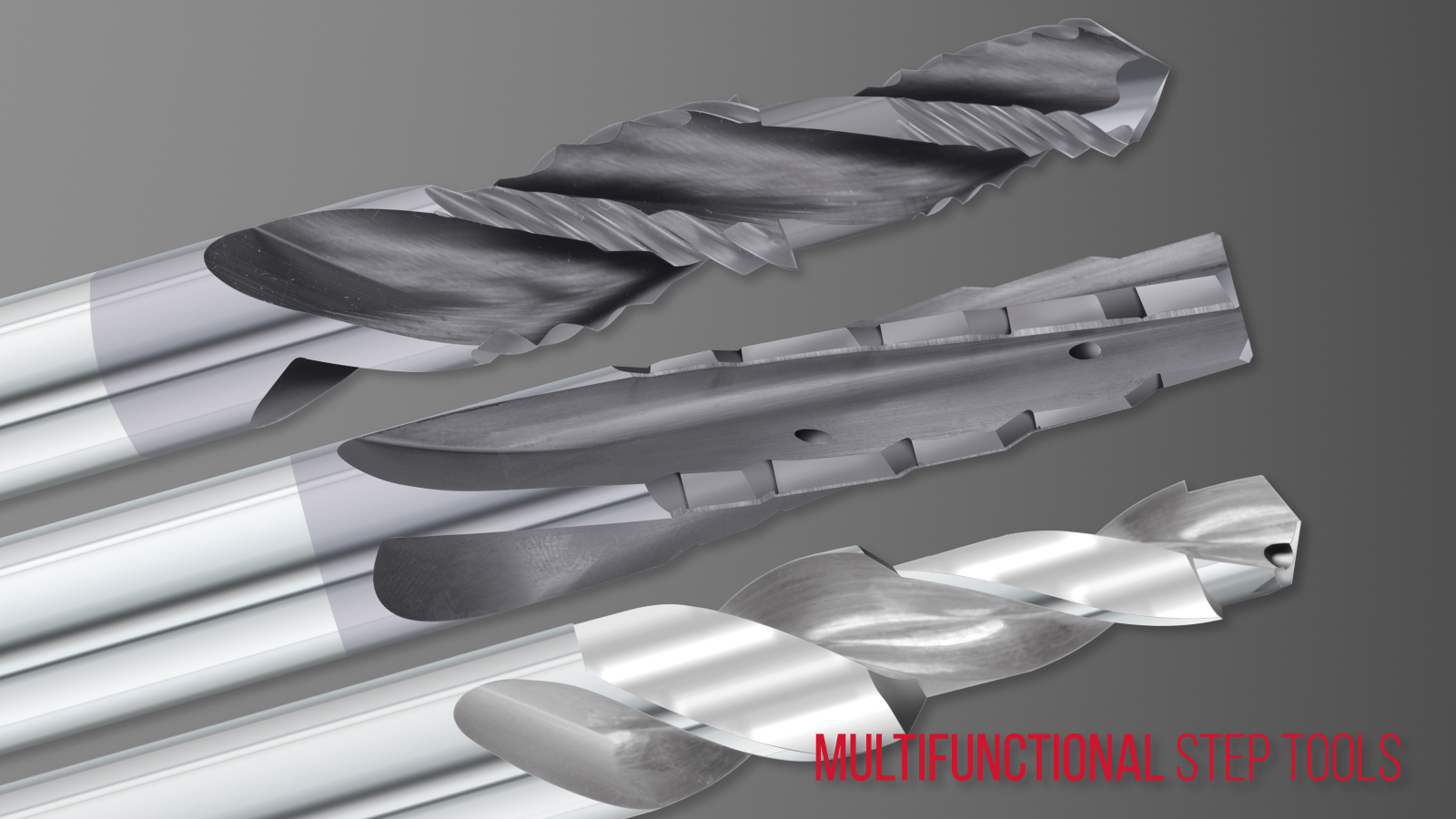

Multifunctional Step Tools

Your business makes its money when your machine is making parts. For jobs that require multiple operations, changing tools can take time away from that manufacturing process. This is where multifunctional, step tools can make all the difference. Combining multiple operations into one tool enables a shop to purchase fewer tools, improve production efficiency by reducing cycle time, and gets products to market faster, all impacting the bottom line.

Your business makes its money when your machine is making parts. For jobs that require multiple operations, changing tools can take time away from that manufacturing process. This is where multifunctional, step tools can make all the difference. Combining multiple operations into one tool enables a shop to purchase fewer tools, improve production efficiency by reducing cycle time, and gets products to market faster, all impacting the bottom line.

Fullerton's team employs a simple strategy, a mindset for cost savings thru process optimization. Tools designed with today's competitive marketplace, machine tool capabilities, and the fewest possible tool changes. Today's multifunctional tool options can combine operations such as drilling, milling, reaming, ramping, interpolation, spotting, chamfering, or counterboring and even etching on a single tool.

Process Reliability

Consideration to operational sequence and combining features in a single tool gives shops the ability to hold critical tolerances, improving dimensional control, tolerance stack ups and process constraints, increasing process reliability and production consistency. When producing parts across a combination of operations, it can become consistency. When producing parts across a combination of operations, it can become difficult, if not impossible, to maintain high levels of accuracy. Multifunctional tools stabilize the manufacturing process by allowing parts to be cut to completion with a single setup. This makes it much easier to hold tight tolerances, while reducing variables.

Reduced Cycle Time

CNC machines use tool changers, and depending on the style of tool changer, it can take anywhere from 15 to 20 seconds from cut stop to cut start to change over tools. Depending on the number of changeovers needed, this time can add up.

Inventory Management

One of the most obvious benefits of multifunctional tool is in inventory management. Replacing multiple tools even across multiple parts with a single tool that can perform all operations is not only a smart option, but also an economically advantageous one.

Whether looking for higher productivity, tighter tolerances or increased capacity, multitask machining can help a shop achieve its goals. The technology has proven itself, and companies that take advantage of its benefits will likely find themselves with an advantage over the competition.

At Fullerton it is important for us to improve our productivity and reduce costs associated with your current CNC machining capabilities.

Contact our Engineering team at 800.248.8315 or engineering@fullertontool.com for help to determine your goals and requirements to improve your business.