Check out our latest Tool Tip which discusses Thermal Conductivity as related to materials vs. carbide.

Material Thermal Conductivity

Thermal Conductivity Basics

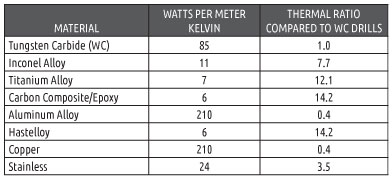

As shown in the table above, the number is measured in Watts per Meter Kelvin (W/m-K). Materials with higher numbers represent a better conductor of heat. The materials shown with higher numbers are better used as a heat sink to absorb heat through thermal transfer. As shown in the thermal ratio column, the difference is shown between the prospective material being machined and Tungsten Carbide. Any number shown below 1 is a material with higher conductivity than Tungsten Carbide (WC). The ratios listed higher than 1 are materials that are considered heat resistant materials.

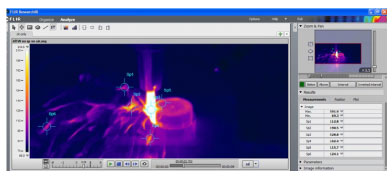

The image above shows the amount of heat generated when machining a profile. The above chart shows the ratio at which the carbide will absorb the heat while machining. The materials, as you can see from the image above, do not absorb heat. This creates thermal damage to the carbide if you do not pay attention to the amount of contact the carbide has with the work piece.