Have you heard the term HEM, high-efficiency machining, or high-speed machining thrown around and not sure what it is? Well in this article I will be explaining what it is, how it works, and why you should use it.

What is High-Efficiency Machining?

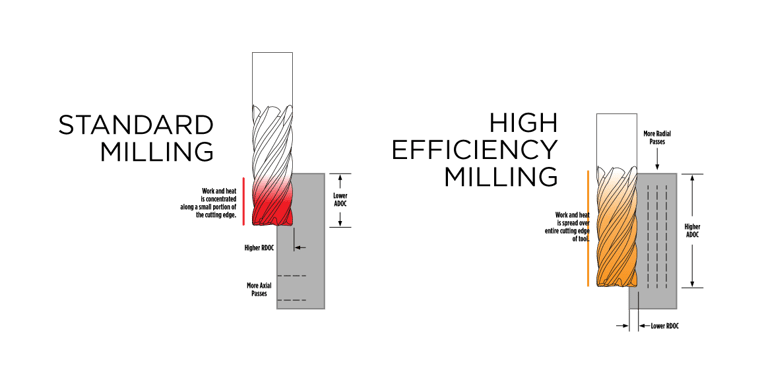

High-Efficiency Machining or High-Speed Machining is a machining methodology that focuses on extremely fast but light, low-pressure cuts. The result is an overall increase in the material removal rate. The milling technique is used where the radial depth of cut (RDOC) is less than 30% (usually 5-10%) of diameter and axial depth of cut (ADOC) is as deep as the tool or parts allow. Using the entire length of cut (LOC) if possible.

Check out our diagram below comparing Standard Milling to High-Efficiency Milling.

Why Use High-Efficiency Milling?

You should use high-efficiency/high-speed machining because it results in increased metal removal rates, reduced cycle time, increased tool life, and much more.

How Does HEM work?

High-efficiency/high-speed machining works based on lowering heat generated in the tool. A small radial depth of cut (RDOC) results in a small angle of engagement. The end mill cutting edges spend less time in cut, resulting in less heat buildup. This allows for much higher SFM. When using HEM, you also can use radial chip thinning (RCT).

Radial Chip Thinning

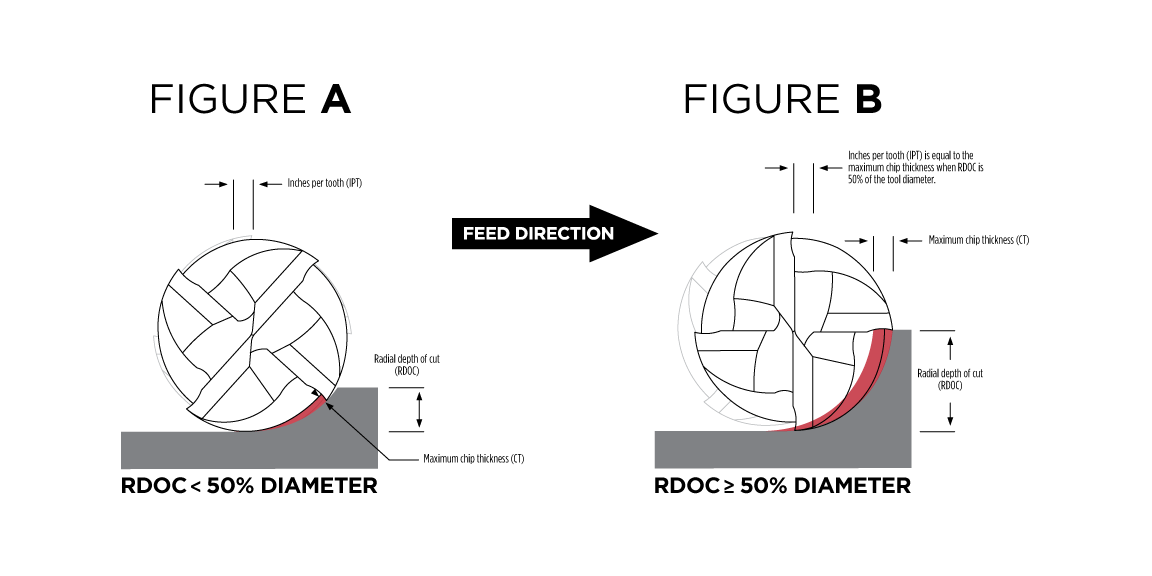

Radial Chip Thinning (RCT) is calculated when taking a <50% of the diameter of the radial depth of cut (RDOC).

When <50% RDOC, the calculated chip thickness is not the actual chip thickness.

By calculating the actual chip thickness, we can increase the feed rate to achieve desired chip thickness. Check out our diagrams below for more information.

Hope you have a better idea of what high-efficiency/high-speed machining is now.

Hope you have a better idea of what high-efficiency/high-speed machining is now.

Need help calculating speed and feed rates for your high-efficiency machining? Check out our End Mill Speed & Feed Calculator at https://fullertontool.com/calculators/high-performance-end-mill (login is required).